Motivation

- Efficient development of WAAM components through knowledge of 3D geometry (shape fidelity) and geometry modification

Objective

- Check shape accuracy with high precision (nm range)

- Measure shape changes over different time scales

Procedure

- Check form accuracy with high precision (nm range)

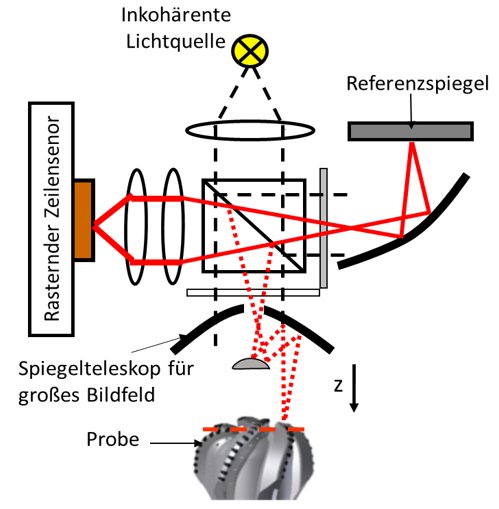

- Measure changes in shape over different time scalesMeasuring principle: Coherence scanning interferometer

- Capture shape data with high resolution and repeatability...

- ...even at high ambient temperatures

- Process and archive data quickly