Multifunctional metal-based structures

- Production of components from multi-material structures with

- different metallic materials

- Non-metallic materials in a metallic matrix

- Creation of structures with local property customization

- Adapted physical / chemical / mechanical properties

- Targeted adjustment / use of cavities / porosities

- Improved surface properties (e.g. wear, friction, etc.)

- Development of suitable base materials / powders

- Alloy development, use of additives (flux, etc.)

- Surface properties / morphology of filler materials (shape-dependent, e.g. through active grinding, plasma treatment, coating)

- Creation of manufacturing freedom by focusing on the use of additive manufacturing processes: Laser sintering, laser melting, wire arc additive manufacturing (WAAM)

- In-situ influencing of component properties in the manufacturing process itself (path planning, energy input, thermal cycles, etc.)

Contact: Prof. Dr.-Ing. Volker Wesling

Hybrid material composites and fiber composite systems

- Development of new multi-material systems with inorganic top layer and reinforced polymer core

- Acoustic damping (FMLs)

- High transparency with shatter and break-in resistance (NanoGlas)

- Application-oriented structural optimization

- Development of innovative manufacturing technologies for fiber composites (focus: resource efficiency/recycling)

- Development and optimization of manufacturing processes for MMS

- Integration of fiber and/or nanoparticle reinforcement

- Combination of different manufacturing processes into a single-stage variothermal forming and joining process (FMLs)

- Use of sterically stabilized, monomer-specific functionalized nanoparticles to optimize properties (NanoGlas)

- Research into the unique online prepreg technology at CZM (objective: zero-waste production / environmentally-oriented composite material production with consistent material properties)

Contact: Prof. Dr.-Ing. Gerhard Ziegmann

Lightweight construction concepts and material systems

- Identification and further development of approaches to material and conceptual lightweight construction

- Overcoming incompatibilities along the entire process chain from material to component

- Production of energy-efficient lightweight structures with special consideration of all load cases and material conditions

- Development and production of fiber composite structures (injection molding, vacuum infiltration, resign transfer molding, wet pressing)

- Adaptation of material systems and filler materials

- Realization of metallic mixed designs and composite structures using low-heat joining processes (arc and plasma processes, pressure welding, mechanical joining and hybrid joining processes)

- Proof of properties under static, cyclic and dynamic loading → Inclusion of material states (e.g. ageing)

Contact person: Dr.-Ing. Henning Wiche

Surface analysis and functionalization

- All materials and substances interact with their environment via their surfaces

- Many material-specific properties such as adhesion, wear or corrosion resistance are largely determined by the surface

- Challenge: High demand for control and insight into the physico-chemical processes on surfaces

- Targeted use of various analysis methods and techniques from the field of surface physics and material analysis

- Dielectrically impeded discharges (DBE plasmas) for the modification and functionalization of surfaces

Contact: Prof. Dr. Wolfgang Maus-Friedrichs / Dr. rer. nat. René Gustus

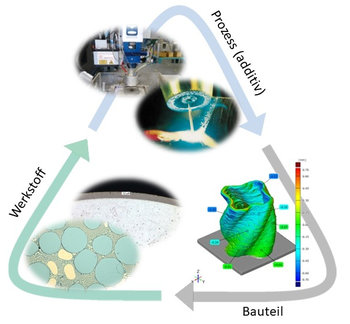

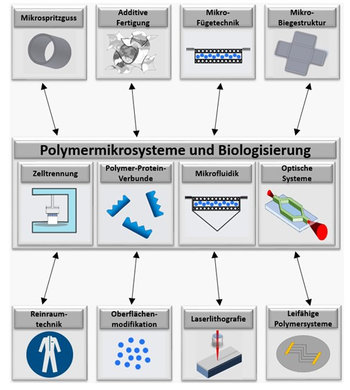

Future clusters: polymer systems, microsensor technology and biologization

- Modeling and simulative design of complex geometries and microcomponents for high-precision applications

- Production and optimization of the process chain using additive manufacturing, laser lithography, micro injection moulding and micro joining technology, taking into account specific boundary conditions

- Material technology

- Biological/medical

- Optical/sensory

- Development of novel material combinations, such as polymer-protein composites, for biological and medical applications under cleanroom conditions

- Development of foldable substrates for optical applications

- Development of conductive polymer systems for microsensor technology

- Research and development of coupling mechanisms for material combinations in a wide range of areas, such as medical technology, optical systems, MID technology, etc.

Future cluster: Solid and pressure-based hydrogen storage systems

- Reliable storage options are necessary for the large-scale use of green hydrogen as an energy carrier

- Areas of application are: Energy industry, mobility sector, production sector

- Problem: high diffusibility, high hazard potential

- Pressure storage using hybrid material systems

- Development of new diffusion barriers

- Consideration of lightweight construction aspects (metal / FRP laminate mixed construction methods)

- Solid-state accumulators based on metal hydride

- Use of DBD plasmas to support storage and retrieval