More than ever, modern components require a balanced mix of lightweight construction and high functionality. However, aspects such as environmental compatibility, costs and process times are just as important as the technical solution. In the field of fiber-reinforced plastics, prepreg semi-finished products have proven to be particularly suitable due to their simple and good processing possibilities in various branches of industry.

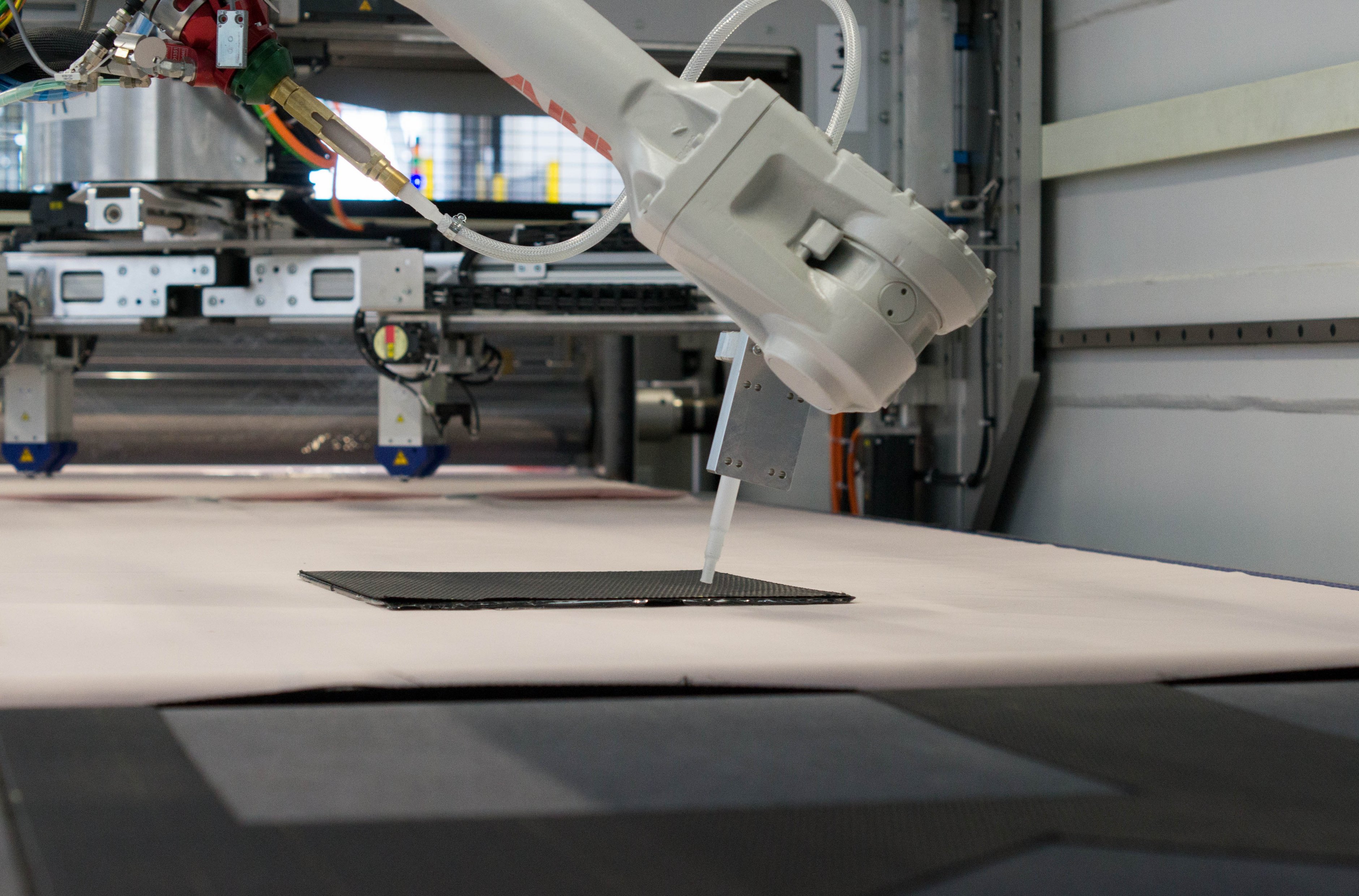

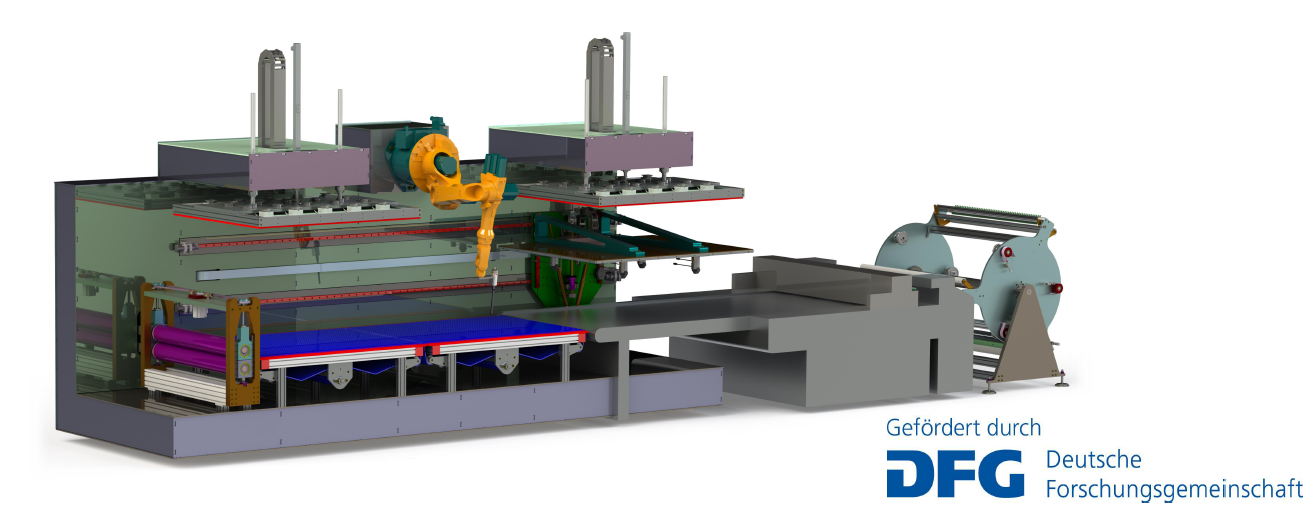

As part of this project, a new type of processing plant is being designed, built and tested, which will set a new standard in prepreg technology. Improved utilization of raw materials, the avoidance of contaminated waste and the reduction of energy consumption are just as much the focus of the research as the development of highly complex components, the shortening of process times and the improvement of the mechanical properties of the end products.

Fiber composites are used in high-performance components for the aerospace industry, mechanical engineering, the automotive industry and the sports sector. They impress with their excellent mechanical and physical properties. In the field of these materials, so-called prepregs are particularly in demand due to their simple and good processing possibilities. In this context, Prof. Ziegmann describes the latest developments at the Clausthal Center for Materials Technology.