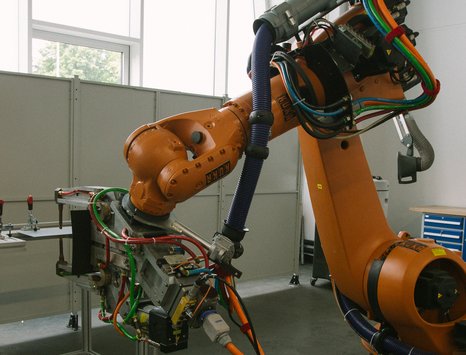

KUKA KR210-2

- Robot system for handling heavy loads, especially in combination with ARO spot-welding gun in X version incl. automatic milling unit for mapping production-like manufacturing conditions in body construction

- Max. Reach: 2,700 mm

- Nominal load capacity: 210 kg

- Number of axes: 6

- Position repeatability: +/- 0.06 mm

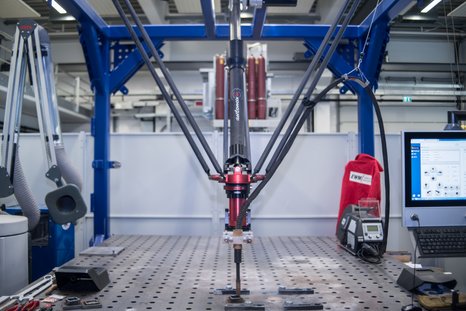

GULLIVER 3D printing system

- Device for additive manufacturing of large-volume bodies using Wire Arc Additive Manufacturing (WAAM)

- Installation space: max. ø1600 mm x 1600 mm

- Maximum component weight: 4 t

- Stiff base frame

- Delta robot as a machine for the "print heads" and other additional equipment

- Sensors: geometry sensor, thermal camera

- Control system

- Height-adjustable build-up table

- Quick-change and temperature-controlled build plates

- 1 or more gas metal arc welding systems (GMAW) for the WAAM process

- 1 or more drilling/milling heads

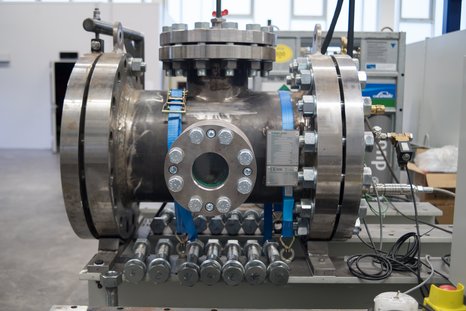

High-pressure tanks for MIG/MAG welding applications

- High-pressure container for hyperbaric MIG/MAG welding

- Influencing the penetration depth and arc behavior through the hyperbaric environment

- Use of current contact tubes specially adapted to the increased pressure

- Dimensions: ø406 mm x 800 mm

- max. ambient pressure: 50 bar

- Integrated linear table for feed realization

- hermetic feed-throughs for electrical connections, table feed and measuring application

- Lumi double sight glass DN100-50PN for process observation

- shielding gases: Ar, Ar/CO2, Ar/He